Textile is an ancient and vigorous science, which plays a decisive role in the history of human civilization. China is the largest producer and exporter of textiles and clothing in the world. Since the reform and opening up, China's textile industry has developed rapidly and has obvious comparative advantages in the world. It has played an important role in increasing the accumulation of national economy, solving employment, improving people's living standards, earning foreign exchange through export, and supporting industries. At the same time, it has also actively promoted the solution of the three rural issues and the improvement of rural urbanization. With the continuous growth of domestic demand and the expansion of international market, the textile industry will still be in a rapid growth trend.

With the continuous development of the textile industry, the pollution problem of China's textile industry has reached the point of urgency. In order to improve environmental pollution, the burner plays an important role. The burner is an important supporting equipment in textile production, providing thermal energy support for drying, dyeing, sizing and other processes.

In the textile industry, the finalization of the cloth surface is the most important part of printing and dyeing. The processing level directly affects the neatness, width and stability of the cloth surface. The main process conditions for shaping are no more than temperature, time, tension and swelling agent. The temperature is the most important factor affecting the setting quality. The adjustment ratio of the burner is as high as 1:40, with accurate temperature control and more energy saving. Output adjustment analog quantity or three digit floating point can be used, and the electrical interface can be customized according to customer requirements. Natural gas and liquefied gas can be used for direct ignition and ionization flame detection, which is more convenient.

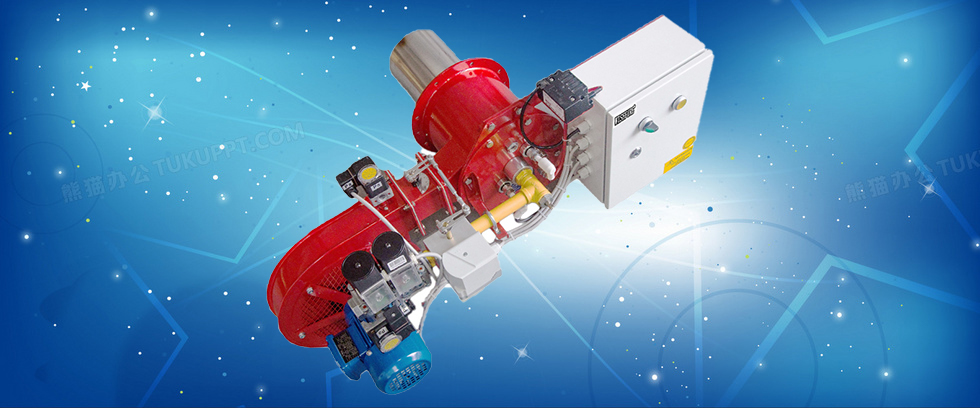

The industrial burner is designed as a compact structure, which is convenient for installation, operation and maintenance. The unique design takes into account the economy, reliability of operation and environmentally friendly combustion. With the CFD optimized fluctuation mode, the air pressure measurement loss is low, and the electric energy consumption is reduced by 50%. Combined with the large adjustment range, the burner is more energy-saving.

As an important equipment in the production line of various industries, NOKEBiNi has provided services for many users in China. In the future, GACO is bound to bring heat source support for more production enterprises to stabilize the economy, and work together with enterprises to drive the global trend of the industry.

近日,在推动清洁能源与环保技术的进程中,加科燃烧器与晋煤控股集团山西同煤电力环保科技有限公司达成重要合作。山西···

在当今全球绿色低碳发展的浪潮中,能源装备行业正经历着变革。作为行业内的佼佼者,加科燃烧器凭借其卓越的技术实力和···