Changle Yili Chemical Co., Ltd. is located in Zhuliu Town Industrial Park, Changle County, Shandong Province. It is adjacent to the 309 National Highway and Jiqing Expressway to the north, and the Nanlin Jiaoji Railway to the south. With a superior geographical location, covering an area of 80 acres and fixed assets of 50 million yuan, Changle Yili Chemical Co., Ltd. is a high-tech private enterprise mainly engaged in the production of fine chemicals. Its main products are environmentally friendly high boiling point solvents, mixed dimethyl adipate (DBE), and dimethyl adipate (DMA), which DuPont Company refers to as similar products, Annual production of mixed acid dimethyl ester is 10000 tons, and dimethyl adipate is 4000 tons. The products are exported to Europe, America, Australia, Southeast Asia, and Taiwan.

Since its establishment, the company has been striving for excellence, strict management, stable product quality, and prioritizing corporate reputation, receiving unanimous praise from domestic and foreign customers.

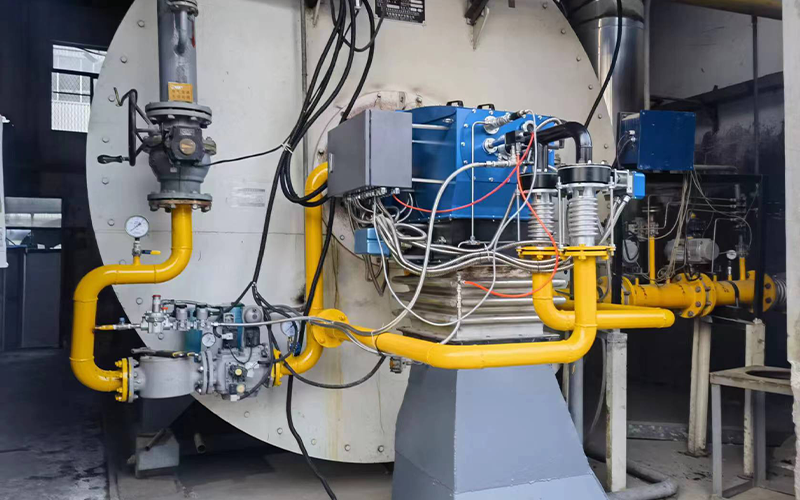

GACO has become a service provider for the burner of Yili Chemical Co., Ltd. with its strong comprehensive strength and comprehensive enterprise philosophy of meeting customer needs. Jiake has sent technical teams to the site multiple times to inspect the working conditions, process materials, and special requirements for adaptive equipment. After detailed calculations, a non-standard hot air burner has been customized for it, This series of burners is a compact electronic proportional adjustment digital burner designed and developed for thermal oil furnaces and hot air furnaces. It adopts a unique technological route to consciously revolutionize the burner, allowing precisely measured gas and air (oxygen) to enter the thermal oil furnace chamber, utilizing the original temperature of the thermal oil furnace chamber (usually 200-400 ℃ for working thermal oil medium) and hot air temperature. Natural gas undergoes uniform oxidation at this temperature, generating infrared heat that is absorbed by the furnace, close to the heat conducting oil pipe in the furnace. Due to the absorption of heat, the temperature in the central area is relatively low, resulting in a temperature difference. This will generate thermal convection. The entire furnace will produce low oxygen oxidation phenomenon (air) without local high temperature zone, and the boiler parameters are reasonably and stably controlled to achieve environmental protection and energy conservation goals